The Process Data Object (PDO) is a type of periodic data object that can be used to exchange data between an EtherCAT master (KINGSTAR Runtime) and EtherCAT slaves (drives or IOs) during each EtherCAT communication cycle, typically every 1 millisecond. The master can monitor and control the slave devices through process data exchange.

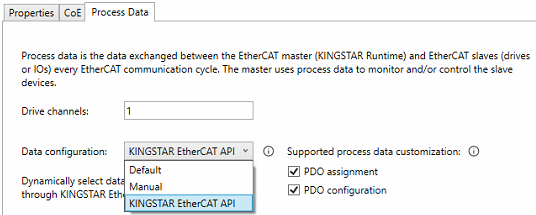

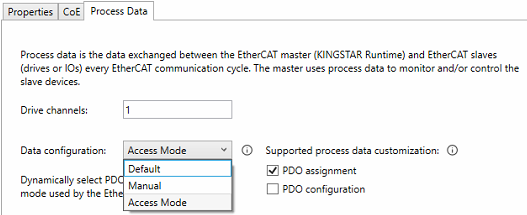

The KINGSTAR ESI Import Tool is provided for users to select the desired type of process data configuration for their devices for the purpose of process data exchange. There are four types in total: Default, Manual, Access Mode and KINGSTAR EtherCAT API.

• Default:

- Use the default PDO combinations specified in the ESI file of the device for process data exchange.

- Criteria for choosing this configuration type: none

- Setup steps:

- Select Default from the Data configuration drop-down list, the supported PDOs and the corresponding variables (PDO entries) will be displayed in the below area. The device will use these default PDO combinations for process data exchange.

NOTE: Generally, when the Default type is selected, there is no need to edit the variables. However, if you find that the default variables are incorrect, you can proceed to edit them. To edit the variables, check the Enable editing checkbox, and then click the Add button to add the desired variables, click the Edit button to edit the variables or click the Delete button to remove the variables.

• Manual:

- Manually select the PDOs and the corresponding variables (PDO entries) for process data exchange. The variables that can be selected depend on the attributes of the PDOs, as well as the supported PDO assignment and PDO configuration of the device.

- Criteria for choosing this configuration type: the devices should support the PDO assignment or PDO configuration.

- Setup steps:

- Select Manual from the Data configuration drop-down list, the KINGSTAR ESI Import Tool will automatically detect and display the supported PDOs and the corresponding variables (PDO entries) of the device in the below area.

- In the Input Process Data Objects or Output Process Data Objects field, toggle the Status switch to enable or disable the desired PDOs for process data exchange. Then click the Add button to add the desired variables, click the Edit button to edit the variables or click the Delete button to remove the variables.

NOTE: If your devices support PDO assignment, then you can select the PDOs. If your devices support PDO configuration, then you can edit the variables. For more details about how to set up PDOs in Manual mode, please see Customize PDOs for Devices.

• Access Mode:

- Allow users to select different PDO combinations for different KsAccessMode.

- Criteria for choosing this configuration type:

- The device should support the PDO assignment, but not support the PDO configuration.

- The device should be a drive (I/O is not supported).

- Setup steps:

- Select Access Mode from the Data configuration drop-down list, the KINGSTAR ESI Import Tool will automatically detect and display the supported PDOs and the corresponding variables (PDO entries) of the device in the below area.

- If you want to select the PDOs, in the Input Process Data Objects or Output Process Data Objects field, check the desired PDOs for each of the KsAccessMode (P, V, T, PV, VP, PVT, VPT).

NOTE: Generally, there is no need and not allowed to edit the variables unless you find that the variables are incorrect, then you can proceed to edit them. To edit the variables, check the Enable editing checkbox and then select a PDO, the corresponding variables will be displayed in the below area. Click the Add button to add the desired variables, click the Edit button to edit the variables or click the Delete button to remove the variables.

• KINGSTAR EtherCAT API:

- Automatically select the variables (PDO entries) for process data exchange through KINGSTAR EtherCAT API calls.

- Criteria for choosing this configuration type:

- The device should support the PDO configuration.

- The device should be a drive (I/O is not supported).

- Setup steps:

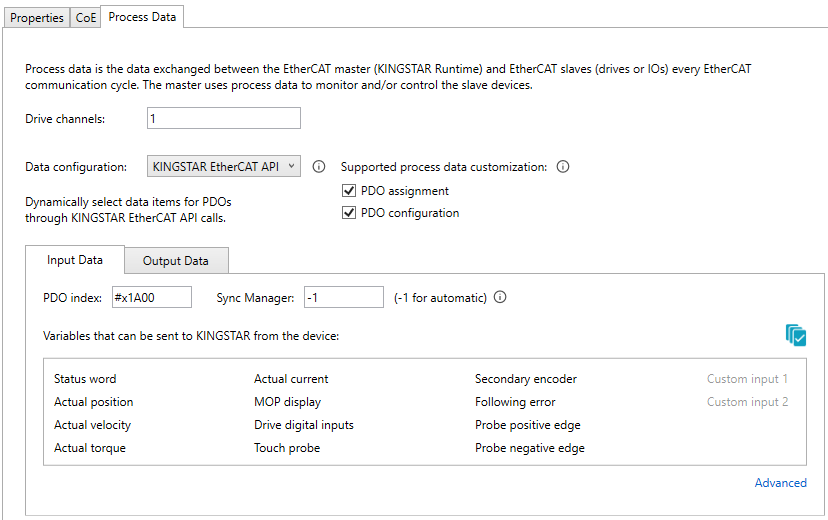

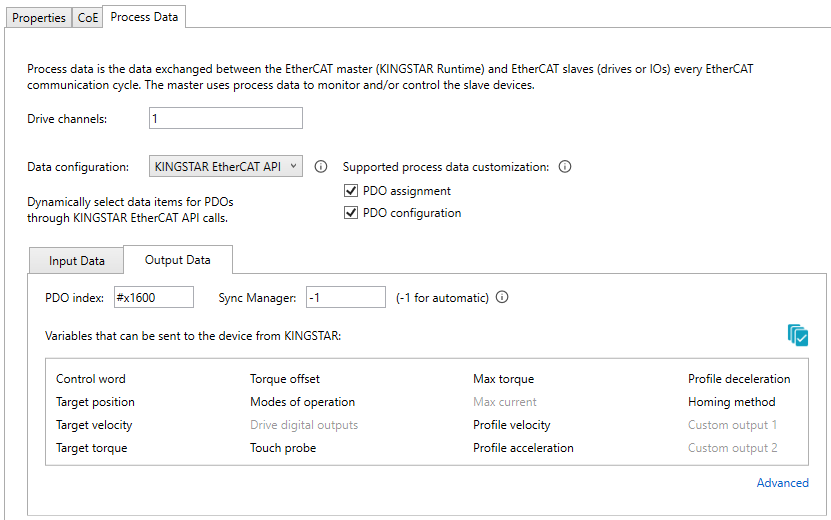

- Select KINGSTAR EtherCAT API from the Data configuration drop-down list, the KINGSTAR ESI Import Tool will automatically recognize the available variables (PDO entries) of the device.

- Edit the variables using the following KINGSTAR APIs:

- SetAxisAccessMode: Select one of the KsAccessMode, and the KINGSTAR will automatically select the corresponding variables (PDO entries). The KINGSTAR Runtime will decide whether to add the target position/velocity/torque and the actual position/velocity/torque variables to process data exchange according to the KsAccessMode you choose. Note that the associated McControlMode can only be used if the device supports the variables required for the selected KsAccessMode.

- Axis variable: In addition to KINGSTAR automatically selecting the corresponding variables for each KsAccessMode, you can also add the required variables to the process data exchange using the Axis variable APIs. Note: Ensure the required variables are supported by the device.

For .NET Class, please refer to ISubsystem properties (e.g. ActualCurrent, ActualVelocity).

NOTE: Variables in black are supported by the drive; while variables in grey are not supported by the drive and will not be added for process data exchange even if the related KINGSTAR APIs are used.

NOTE: You can also use the KINGSTAR Configuration Tool to configure the KsAccessMode and Axis variable, please refer to Connection Settings > Axis Settings.

Descriptions of the variables supported by KINGSTAR for process data exchange

KINGSTAR ESI Import Tool will automatically detect the supported PDOs and the corresponding variables (PDO entries) of the device and display the variables in the Input Data and Output Data fields.

Input Data (variables sent from the slaves to the master):

Status word: the status of the drive. The status can be "not ready to switch on", "switch on disabled", "ready to switch on", "switched on", "operation enabled", "quick stop active", "fault reaction active", or "fault".

Actual position: the actual position.

Actual velocity: the actual velocity.

Actual torque: the actual torque.

Actual current: the actual current.

MOP display: the value of the modes of operation display variable. The operation mode could be CSP (Cyclic Synchronous Position), CSV (Cyclic Synchronous Velocity), CST (Cyclic Synchronous Torque), … etc.

Drive digital inputs: the digital input of the drive.

Touch probe: the touch probe status of the drive.

Secondary encode: the position from the secondary encoder if there are two encoders.

Following error: the following error.

Probe positive edge: the latched position value after a rising edge of the touch probe.

Probe negative edge: the latched position value after a falling edge of the touch probe.

Custom input 1: a user-defined object. This object must exist in the device's object dictionary.

Custom input 2: a user-defined object. This object must exist in the device's object dictionary.

Output Data (variables sent from the master to the slaves):

Control word: this object is used to set the mode of the drive, which can be read out by status word.

Target position: the commanded position.

Target velocity: the commanded velocity.

Target torque: the commanded torque.

Torque offset: the torque's offset. Used in torque mode.

Modes of operation: this object is used to set the operation mode of the drive, which can be read out by MOP display.

Drive digital outputs: the digital output of the drive.

Touch probe: sends the touch probe command.

Max torque: the maximum torque.

Max current: the maximum current.

Profile velocity: the Profile Velocity.

Profile acceleration: the Profile Acceleration.

Profile deceleration: the Profile Deceleration.

Homing method: the homing method.

Custom output 1: a user-defined object. This object must exist in the device's object dictionary.

Custom output 2: a user-defined object. This object must exist in the device's object dictionary.

Dependency table between functions/APIs and variables

The table below shows the variables that the functions or APIs will rely on for your reference.

| Functions / APIs | Required Process Data Variables |

|---|---|

|

Target position |

|

|

Target velocity |

|

|

Target torque Actual torque |

|

|

Control mode switching while powered on, |

MOP display Modes of operation |

|

Touch probe (input: status) Touch probe (output: control) Probe positive edge Probe negative edge |

|

|

Drive digital inputs |

|

|

Drive digital outputs |

|

|

Actual current |

|

|

Actual torque |

|

|

Actual velocity |

|

|

Second Position |

|

|

Following error |

|

| Torque offset | |

|

Max torque |

|

|

Max current |

|

|

Profile velocity |

|

|

Profile acceleration |

|

|

Profile deceleration |

|

Glossary

- Process data exchange:

Exchange the process data between the EtherCAT master (KINGSTAR Runtime) and EtherCAT slaves (drives or IOs) every EtherCAT communication cycle (usually 1 millisecond per cycle), including sending input data from slaves to the master and sending output data from the master to slaves.

-

PDO:

Process data object. Every process data object contains a group of data items (PDO entries) and can be selected to participate in the process data exchange. Some devices will make certain PDOs fixed (the data items contained in them cannot be changed), or mandatory (must participate in process data exchange)

-

The device supports users to select PDOs for process data exchange.

-

The device supports users to configure the data items in PDOs.

-

KINGSTAR EtherCAT API:

KINGSTAR provides many EtherCAT related APIs. The APIs that affect process data items selection are the Axis variable. For .NET Class, please refer to ISubsystem properties (e.g. ActualCurrent, ActualVelocity).

See also